LearyVIEW Flex

Glue Detection Camera Inspection

The LearyVIEW Flex multi-camera inspection system monitors for glue inside and outside of a specified region of interest with the ability to set different tolerances for the front and the back of the glue patterns. This is a useful feature for beverage carriers to reduce waste by allowing some variation of less critical elements while keeping tight tolerances on those that need it. Using our intuitive and simple operating software, the camera solution is able to scan carton blanks, looking for all gluing defects as they travel through the machine.

LearyVIEW Flex camera can also monitor for flaps and folds visible in the field of view. Detect the absence and presence of cutouts and ensure that folds have been correctly made, compared to the learned master image.

Glue outside of the target area or incorrectly folded product, can be identified and rejected to eliminate faulty cartons.

- Inspect glue in desired target area

- Inspect specks of glue outside of target area as small as 2 mm wide

- Monitor for flaps and folds visible in the camera’s field of view

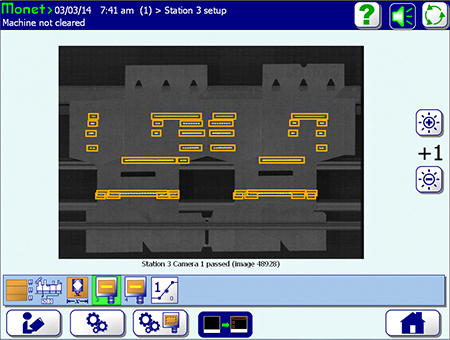

- Simple setup with the Monet operating system version 3.0

- Remote diagnostic capability for post-installation support

- Ideal for beverage carriers, high-speed straight-line cartons, confectionary and stencil glue patter cartons

Software Overview

Monet software technology enables unique advancements in vision inspection. Traditional solutions detect from the front to the back of the carton and can only detect anything within their narrow field of view. Leary’s solution monitors for any misplaced or transferred glue anywhere on the carton, in addition to checking for the correct presence, placement and width of glue lines at maximum speeds.

Resources

Solutions For Your Industry

Leary solutions are offered to improve plant efficiencies, decrease setup time, increase uptime and lower product waste, regardless of machine type.