Spray Rejection

Atomizing Spray Valve for Product Marking

Some machines may not have room for an ejection system. In this case Leary offers a spray rejection option using a Jet250 valve.

Our system will identify each bad product and activate the spray valve so the defective product can be identified and manually removed at the end of the machine. Our atomizing spray valve will only mark the product at a specific location. This device has a manual adjust air intake port which can increase or decrease the amount of moisture and the pressure of the spray mist. Additional flow controls are accessible at the pressure tank and FRL.

The pressure tank is usually filled with water and either colored or tinted with UV. If tinted, the sprayed mark will only be detected under a UV lamp.

- Atomized spray head

- Accurately marks product with volume control

- 1 ms response time

- Compact design

- Gun dimensions: 107 mm (4.25 in) x 50 mm (2 in)

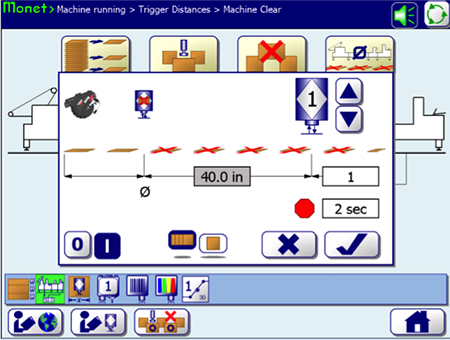

Software Overview

Ensuring accurate removal of faulty product is vital to delivering quality product. Leary’s Monet software integrates advanced technologies to guarantee that the exact marked defective product is removed. Key data points including multiple machine distance inputs track product and account for its completion. Leary’s rejection technology also includes unique machine clear options. Choose from machine or feed stop machine clear to eliminate product that has not gone through all required quality checks - this maintains quality product.

Resources

Solutions For Your Industry

Leary solutions are offered to improve plant efficiencies, decrease setup time, increase uptime and lower product waste, regardless of machine type.