In-Line Diverter

Inline Retrofit Rejection for Your Current Gluer

Leary offers the only In-Line Diverter rejection device to retrofit to your existing machine. The In-Line Diverter can eject the widest variety of style and size carton with minimal operator setup for new jobs. This solution pushes product down from the machine, eliminating any product style or size impediments. This rejection device can also handle multiple rejects and machine clear functions without additional stress and pulling on gluer belts – typical with cartons rejected to the side of a gluer – which can lead to belt removal at times.

The In-Line Diverter ejector is mounted in the trombone section of the folder-gluer and works well with all carton styles. This device is designed to work with all Leary controllers and has a compensation feature which automatically adjusts the activation time based upon carton size, gap and machine speed.

- Less than 25 ms response time

- Retrofit to most folder-gluers

- Rated at 650 m/min (2,130 ft/min)

- Robust design

- Eliminate lengthy set up time

- Ejects the widest range of product shapes and size

- Safety guard for moving pieces

Software Overview

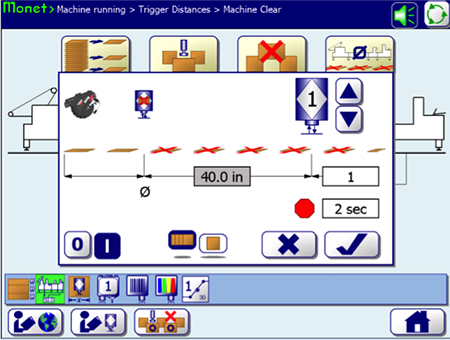

Ensuring accurate removal of faulty product is vital to delivering quality product. Leary’s Monet software integrates advanced technologies to guarantee that the exact marked defective product is removed. Key data points including multiple machine distance inputs track product and account for its completion. Leary’s rejection technology also includes unique machine clear options. Choose from machine or feed stop machine clear to eliminate product that has not gone through all required quality checks - this maintains quality product.

Resources

Solutions For Your Industry

Leary solutions are offered to improve plant efficiencies, decrease setup time, increase uptime and lower product waste, regardless of machine type.