Cold Glue Feed Delivery

Pump and GRU Solutions for Accurate Application

Leary’s line of cold glue feed pumps and GRU’s have been designed to deliver extremely accurate glue line volume control, despite adhesive variance. Glue feed solutions utilize advanced technology via closed-loop communication between the GRU, pump and controller to maintain precise application. Each glue feed system can be matched to specific controllers and cold glue valves for optimum performance.

Adaptable For Your Application

Adaptability to a variety of glue requirements is an important component of Leary’s glue delivery system. Glue feed solutions eliminate puddling, glue line variation, glue pattern drifting and maintains pressure continuity to create a consistent glue line pattern. Pressure requirements can also be programmed and maintained throughout a wide speed range.

For applications where very high glue volume is required from a large number of glue valves such as beverage basket carrier cartons or other special applications, Leary recommends using the High Pressure Diaphragm Pump feed system. This pump’s high adhesive flow, low cycle rate, and static seals maintain accurate application for an extended period of time with minimum maintenance.

- Consistent and accurate glue application

- Closed-loop communication with GRU and controller to maintain constant glue pressure

- Long lasting design with high performance pump shaft seals

- Multiple options for ideal performance

- In the field maintenance option eliminates long downtimes

- Upgrade and rebuild kits available

Choose from Glue Feed and GRU options to meet your gluing requirements:

| Low Pressure Tank | Low Pressure Pump | Medium Pressure Pump | High Pressure CXU 110 Pump | High Pressure Diaphragm Pump | |

|---|---|---|---|---|---|

| Pump | 1:1 | 4:1 | 9:1 | 4:1 | |

| Fluid Regulation | 2:1 | 2:1 or 5:1 | 6:1 | 6:1 | |

| Glue Viscosity Range* | 0.2 – 0.6 Pa·s / 200 – 600 cps | 0.2 – 0.6 Pa·s / 200 – 600 cps | 0.3 – 2 Pa·s / 300 – 2,000 cps | 0.5 – 12.5 Pa·s / 500 – 12,500 cps | 0.2 – 15 Pa·s / 200 – 15,000 cps |

| Max Fluid Pressure | 6 bar (80 psi) | 6 bar (80 psi) | 11 bar (160 psi) or 16.5 bar (240 psi) | 30 bar (435 psi) | 16.5 bar (239 psi) |

| Pressure Dumping | ● | ● | ● | ● | |

| Actual Pressure Reading | Optional | Optional | Optional | ||

| Closed-loop Communication | ● | ● | ● | ● | |

| 100% Stainless Steel | Optional | ||||

| Max. Valve Outputs | Up to 24 | Up to 24 | Up to 24 | Up to 24 | Up to 64 |

| * The viscosity range quoted relates to this product only. For viscosity ranges for the complete system, please also check the relevant glue valve data. | |||||

| Low Pressure Tank | |||||

|---|---|---|---|---|---|

| Glue Viscosity Range* | |||||

| 0.2 – 0.6 Pa·s / 200 – 600 cps | |||||

| Max Fluid Pressure | |||||

| 6 bar (80 psi) | |||||

| Max. Valve Outputs | |||||

| Up to 24 | |||||

| Low Pressure Pump | |||||

| Pump | |||||

| 1:1 | |||||

| Fluid Regulation | |||||

| 2:1 | |||||

| Glue Viscosity Range* | |||||

| 0.2 – 0.6 Pa·s / 200 – 600 cps | |||||

| Max Fluid Pressure | |||||

| 6 bar (80 psi) | |||||

| Pressure Dumping | |||||

| ● | |||||

| Closed-loop Communication | |||||

| ● | |||||

| Max. Valve Outputs | |||||

| Up to 24 | |||||

| Medium Pressure Pump | |||||

| Pump | |||||

| 4:1 | |||||

| Fluid Regulation | |||||

| 2:1 or 5:1 | |||||

| Glue Viscosity Range* | |||||

| 0.3 – 2 Pa·s / 300 – 2,000 cps | |||||

| Max Fluid Pressure | |||||

| 11 bar (160 psi) or 16.5 bar (240 psi) | |||||

| Pressure Dumping | |||||

| ● | |||||

| Actual Pressure Reading | |||||

| Optional | |||||

| Closed-loop Communication | |||||

| ● | |||||

| Max. Valve Outputs | |||||

| Up to 24 | |||||

| High Pressure Pump CXU 110 Pump | |||||

| Pump | |||||

| 9:1 | |||||

| Fluid Regulation | |||||

| 6:1 | |||||

| Glue Viscosity Range* | |||||

| 0.5 – 12.5 Pa·s / 500 – 12,500 cps | |||||

| Max Fluid Pressure | |||||

| 30 bar (435 psi) | |||||

| Pressure Dumping | |||||

| ● | |||||

| Actual Pressure Reading | |||||

| Optional | |||||

| Closed-loop Communication | |||||

| ● | |||||

| 100% Stainless Steel | |||||

| Optional | |||||

| Max. Valve Outputs | |||||

| Up to 24 | |||||

| High Pressure Diaphragm Pump | |||||

| Pump | |||||

| 4:1 | |||||

| Fluid Regulation | |||||

| 6:1 | |||||

| Glue Viscosity Range* | |||||

| 0.5 – 12.5 Pa·s / 500 – 12,500 cps | |||||

| Max Fluid Pressure | |||||

| 16.5 bar (239 psi) | |||||

| Pressure Dumping | |||||

| ● | |||||

| Actual Pressure Reading | |||||

| Optional | |||||

| Closed-loop Communication | |||||

| ● | |||||

| Max. Valve Outputs | |||||

| Up to 24 | |||||

| * The viscosity range quoted relates to this product only. For viscosity ranges for the complete system, please also check the relevant glue valve data. | |||||

Software Overview

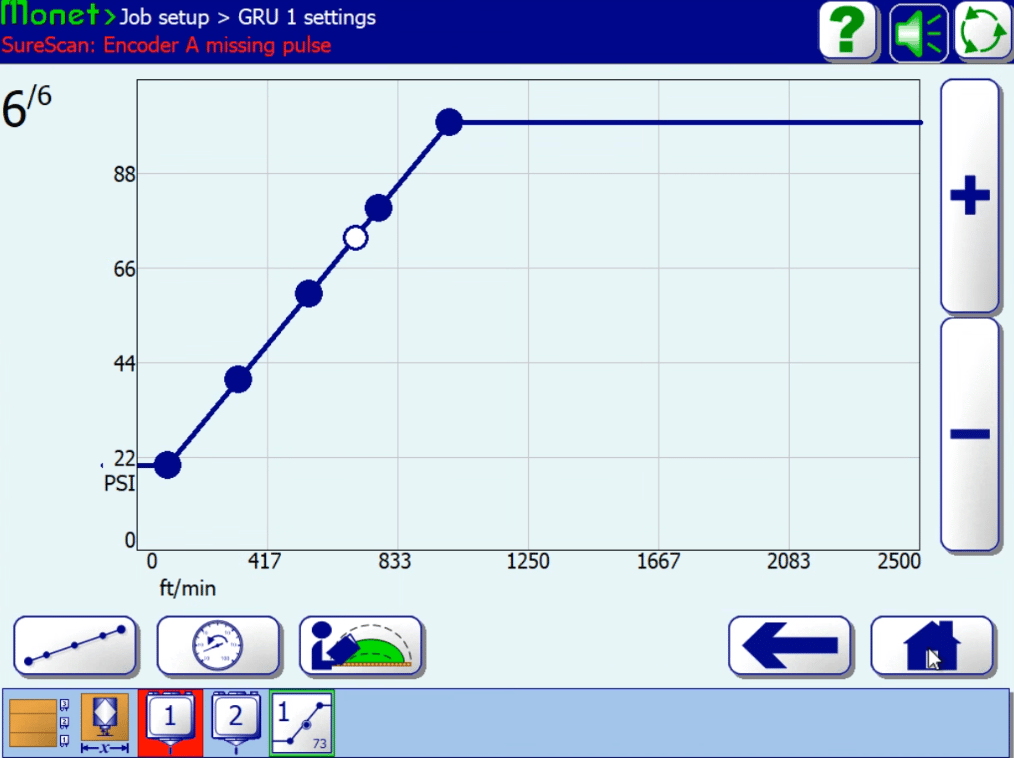

Monet GRU

Maintain proper glue pressure with simple Glue Regulation setup pages in Monet software. The easy to read graph allows visualization of the pressure change in relation to speed. Adjust the pressure curve with ease and make linear, with a touch of a button. Use the Learn Volume button to update volume detection settings.

Solutions For Your Industry

Leary solutions are offered to improve plant efficiencies, decrease setup time, increase uptime and lower product waste, regardless of machine type.