Concept Stream Melter

Hot Melt Glue Feed

Concept Stream, Robatech’s tankless melter for hot melt adhesives with Melt-on-Demand technology assures a fast heat-up time and an efficient and safe production with maximum uptime.

The tankless hot melt system is designed for melting and pumping of thermoplastic hot melt in granular form. It gently melts on demand and therefore is applicable for both high and low glue consumption applications. Thanks to the fast heat-up time of 16 minutes to 160°C the Concept Stream is quickly operational. In addition, the adhesive system achieves a high melting rate performance of 9 kg/h or 15 kg/h with minimum space. View more information on robatech.com.

Innovative melting technology

- 100% increased melting rate – a small tank for high performance (8 kg/h) with minimum space

- MOD (Melt-on-Demand) technology only melts the quantity of adhesive you need, when you need it

- The gentle melting and conveying reduces the risk of charring and nozzle blockage to a minimum and increases the adhesive filter’s life span

- Suitable for applications with low glue consumption

Fast and efficient processing

- Fast heat-up time (16 min) and standby function

- Over 20% energy savings thanks to our GreenLine technology

- Fill level supervision with unique run empty protection for maximum uptime

Highest operator safety

- Safe manual filling by a CoolTouch adapter

- CoolTouch insulated melting unit to minimize burning risks

- Automatic pressure relief

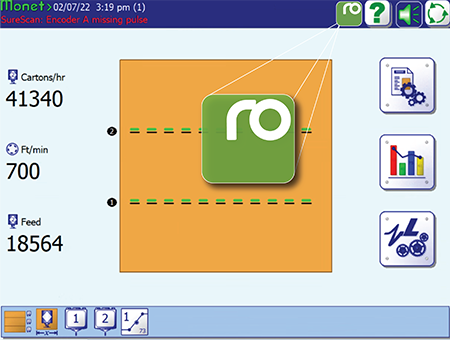

RobaVis Operating System

The new intuitive, graphic touchscreen allows for hot melt controls to be simplified and easily managed. Use RobaVis Host to integrate with Leary’s Monet controller having all cold glue, hot melt and quality assurance controls at your fingertips.

- Task library with supporting diagrams of the end products

- Temperature settings

- Controls compatible with Robatech machines

- User-friendly visualization of patterns and processes

- Other functions e.g. data exchange

Software Overview

Leary’s Monet software integrates seamlessly with Robatech hot melt solutions. Simple setup is available with Robavis touch screen which loads directly onto Leary’s interface. Once hot melt valves are set up, see full operation on Monet screen as product is running.

Solutions For Your Industry

Leary solutions are offered to improve plant efficiencies, decrease setup time, increase uptime and lower product waste, regardless of machine type.