Better Ideas Driven by Quality

Thank you to all of our staff, visitors and colleagues for making drupa 2024 a success!

During this 11-day show in Dusseldorf, DE, Leary delivered Better Ideas Driven by Quality!

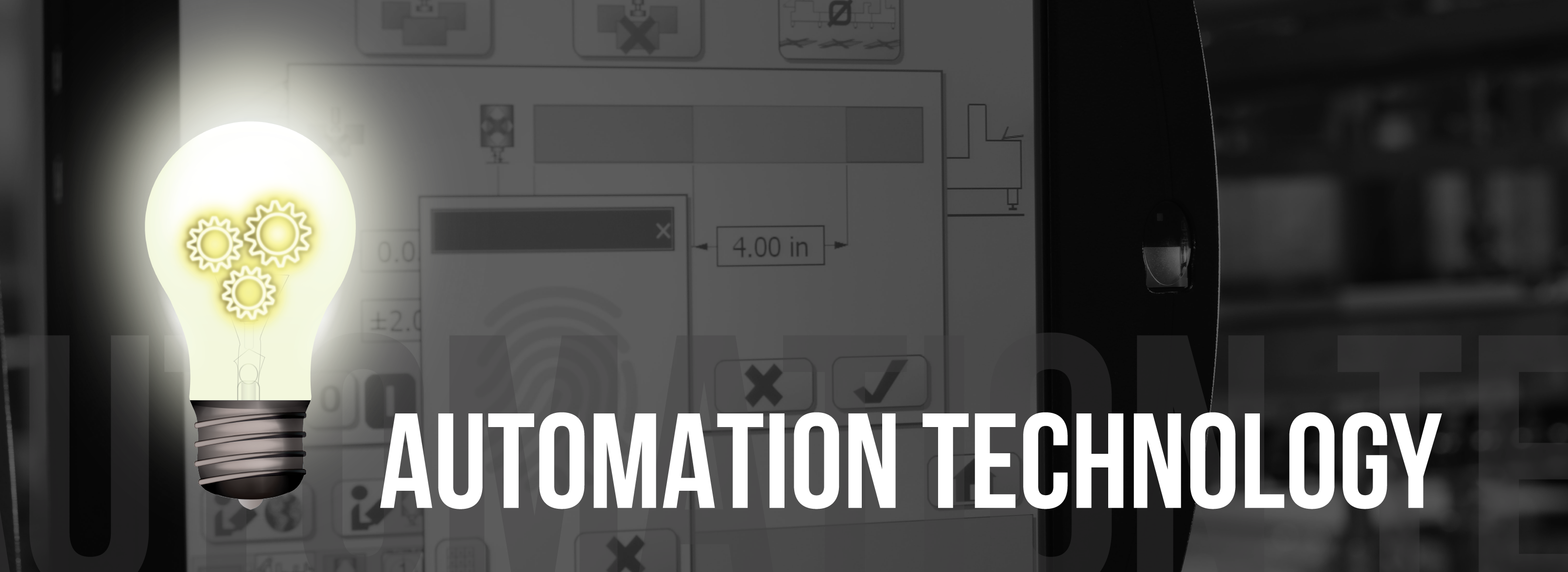

In a world where products, ideas and technologies are readily available, trust Leary to deliver the better, customizable, end-to-end system. These solutions reduce board and glue waste in an automated way, reducing human interaction where unnecessary – delivering quality product, every time.

Leary’s solutions transform your challenge of hiring the right people into an opportunity to improve efficiency with Leary’s cutting-edge solutions.

View our solutions demonstrated during drupa below and reach out to schedule an exploratory call.

Drupa 2024 At-A-Glance

Visitors to Leary’s booth at drupa 2024 learned how plants can pair gluing and quality technologies with unique software to further automate the operation of product creation. By adding this automation technology, plants deliver bench-marked quality in a sustainable way – every time.

Live demonstrations of Leary’s range of gluing, quality inspection and data solutions on a B&R Moll folder gluer showcased quality straight-line folding cartons and an e-commerce cardboard envelopes.

Visit us at Hall 12

Take a walk into Hall 12 on opening day of drupa 2024.

- 18 Leary staff from USA, CA, UK, MX

- 7 Setup days | 11 Show days | 3 Teardown days

- 507 Total hours

- 100% Success

Customizable end-to-end systems. Leary’s patented innovative technologies are at the forefront of the paperboard packaging market offering the most expansive range of gluing, quality assurance, and data collection solutions for delivering quality paper-based packaging.

Our products are bold, using advanced designs for durability, adaptability, and efficiency. From controllers utilizing the most innovative internal processing software, sensor and camera integrations, to rejection technologies that initiate precise single product removal; our solutions improve productivity, minimize downtime and maximize efficiency.

Reduce board and glue waste. Running your plant at the highest level of productivity is sustainable when you decrease product waste, improve production processes and maximize your hardware assets.

Improved software and hardware capabilities use precise technology to operate gluing and quality functions delivering exact adhesives, remove a single faulty product, minimizing job setup and more.

Reduce human interaction. Folding carton plants that utilize automation technology to improve adhesive application and quality control see a signification improvement in production, quality and waste reduction. Leary’s line of solutions focuses on combining unique software and hardware advancements to deliver the same standard of quality product and efficiency required – every time, with minimum human interaction.

Leary’s automation technology allows plants to transform their challenge of hiring the right people, into an opportunity to improve efficiency with Leary’s cutting-edge solutions.

Remote access to minimize downtime. Leary puts customers first by offering premium service and support in all areas. Troubleshooting and software upgrades through remote access is a must, and standard with all new Monet controllers.

Optimal support is achieved through attention to detail and consistent process improvement measures. Leary delivers quick turnaround, remote login support, preventative maintenance programs, and technical training to keep your plants running safely and efficiently.

Industries We Serve

Leary is dedicated to being a leader in manufacturing complete end-to-end solutions that reduce materials and time waste in multiple production environments. Beginning with maximum hardware and software integration to specific machine process, Leary delivers in all areas while reducing human interaction with software automation. Deliver quality product – every time!

Learn about these applications:

Carton | Box | Tray | E-Commerce | Bag | Envelope

A Leader in Manufacturing

Leary is dedicated to being a leader in manufacturing in-process controlling, monitoring, extrusion and data acquisition systems for the packaging industry. As an engineering company, we are continually developing new solutions which help our packaging partners produce products which exceed their customers’ expectations and improve plant performance.