MaQ+ Controller Line

Expandable Gluing and Detection Controller

The MaQ+ (plus) controller serves a growing market of plants looking to expand their gluing and / or quality assurance capabilities. The ease of controller expandability makes the MaQ+ the most cost-effective solution with minimal initial investment expenses and future flexibility for growth.

The MaQ+ comes standard as a base unit with three configuration choices; detection only, extrusion only, or combination extrusion and detection to produce 100% fit-for-use product.

Configurations

This solution can be fully expanded to eight extrusion outputs and three detection inputs – the largest in this controller range. The MaQ+ is ideal for gluing and / or detection on folder gluers, folding machines, die-cutters, bag plants, tray former machines and more. This easy-to-use solution quickly and efficiently implements into your plant’s quality and productivity objectives.

- Available in Gluing, Detection or Combination configuration

- Up to 11 total I/O (3 detection inputs, 8 extrusion valves)

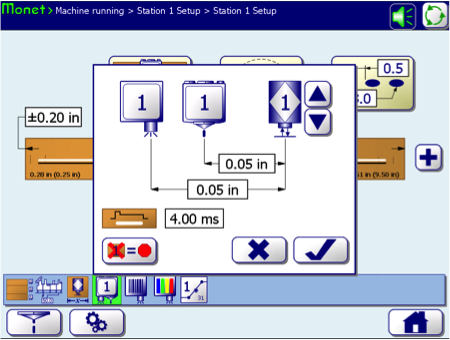

- Monet software interface

- Simple make ready set up times

- iQ Smart Services compatible

- 70+ detection options including barcode reading, glue and more

- Minimal hardware investment

- Expandable gluing module

Detection Only Configuration:

- Up to 3 detection inputs

- Component connections built-in to controller

- Over 70 detection options

- Machine shutdown or rejection options

Extrusion Only Configuration:

- Up to 8 extrusion outputs

- Extrusion module needed

- Glue regulation compatible

- Tip Seal technology

- Easily upgrade to detection

Software Overview

Monet Software

Monet software is designed for quick, simple, job setups producing immediate quality product. Unique capabilities such as rolling password protected settings, and automatic configuration of glue pattern locations are included along with an intuitive layout which reduces operator learning to a minimum.

Solutions For Your Industry

Leary solutions are offered to improve plant efficiencies, decrease setup time, increase uptime and lower product waste, regardless of machine type.