Monet Operating Software

Glue Application and Detection Pictorial Software

Leary’s goal is to give operators a tool to enable them to decrease make-ready time and improve quality and efficiencies. Our Array and MAQ+ controllers, with cutting edge gluing and inspection technology, are paired with Monet software, an interface that is so simple to use that it delivers an immediate cost savings.

- Simple glue application and detection Job Setup

- Language neutral

- Decrease training time

- Increase production and quality awareness

- Controller interface uniformity

- Software upgrade available for existing Leary controllers

- Compatible with iQ Smart Services cloud-based data collection

- Utilize Monet 3.0 for simple integration with camera solutions

MONET operating software has been creatively designed to include features that ensure carton quality is maintained as simply as possible. Intuitive technology to deliver defect-free cartons while increasing production and decreasing downtime.

Monet Software Overview

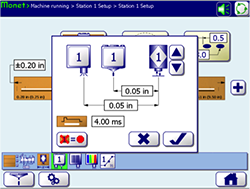

Simple Setup

Simple gluing setup with single page access to all settings needed to apply accurate glue patterns at any speed. QA function such as barcode, inserts and flaps use the same easy to learn interface.

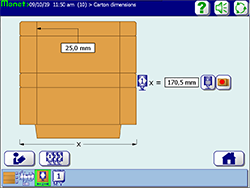

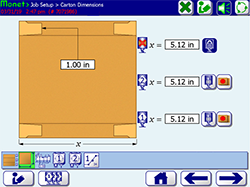

Intuitive Make Ready

Learn carton measurements during the make-ready and automatically program where the glue starts and stops. Images are dynamic and scaled to the carton on the screen.

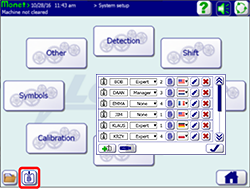

SeQure ID Fingerprint

Maintain carton quality by allowing only approved fingerprints access to critical settings. Record and time stamp any system and setting changes and view the change log in iQ.

Volume Detection

Increase glue detection capabilities by monitoring for presence, placement and volume. Decrease glue usage and ensure against unnecessary squeeze out and stickers.

Surescan

Ensure that each gluing and quality control station is functioning. Cartons are tracked through the machine and if they haven’t been passed by every detection station, they will be rejected.

Fail-Safe Rejection

Track the defective carton to the rejection device and automatically clear the machine after a stop. Choose from separate machine or feed stop to ensure quality is maintained without impeding production.

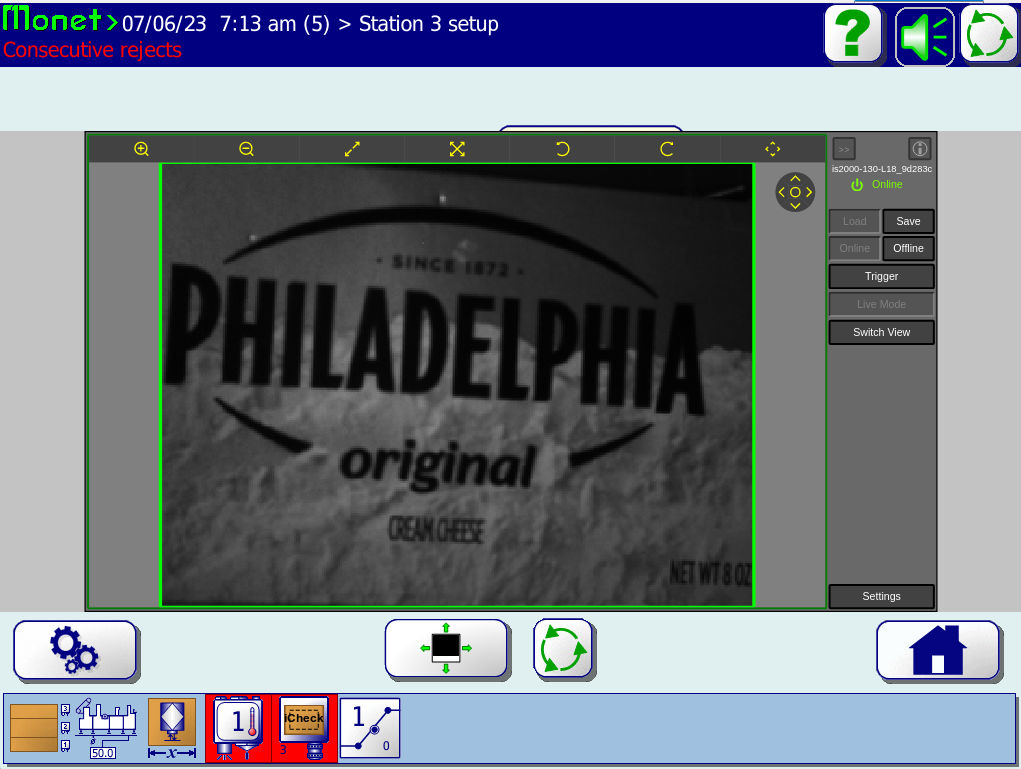

Camera Integration

Seamless integration with camera solutions that use Leary's new Monet 3.0 software.

Solutions For Your Industry

Leary solutions are offered to improve plant efficiencies, decrease setup time, increase uptime and lower product waste, regardless of machine type.