iTac IR Hot Melt Detection

Hot Melt Glue Detection with Quad Amplifier

The iTac IR-2L is a highly advanced hot melt glue detector using infrared technology. It is capable of detecting for glue absence, presence, placement and volume at line speeds in excess of 650 m/min (2,150 ft/min).

Used in conjunction with our MaQ+ and Array line of controllers, this scanner takes a comparison reading between the substrate and hot melt adhesive immediately after application.

The iTac IR-2L works well with the wide range of Robatech hot melt applicator heads, including Coating Head Solutions, Silicone Release Liner Solutions and others.

- High speed detection

- 1 mm (.04 in) @ 650 m/min (2,150 ft/min)

- Glue volume detection

- Remote amplifier for sensitivity adjustments

- Used with all Leary MaQ+ and Array controllers

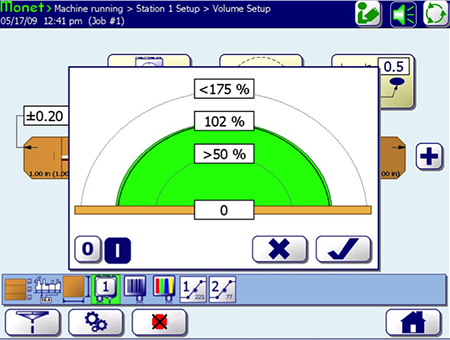

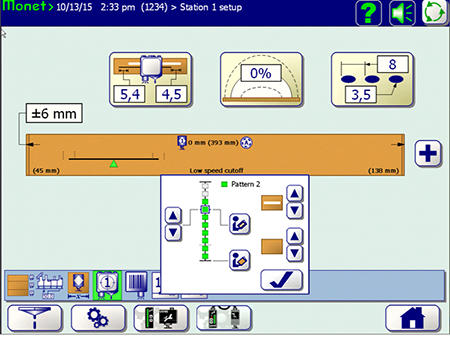

Software Overview

Glue detection capabilities are drastically improved with Monet software technology. Minimize glue usage and ensure against unnecessary squeeze out with the only volume detection solution available.

Fine-tune adjust the sensitivity of glue detection sensors through the Monet screen to avoid crossing safety light curtains which contribute to a plant’s overall efficiency.

Resources

Solutions For Your Industry

Leary solutions are offered to improve plant efficiencies, decrease setup time, increase uptime and lower product waste, regardless of machine type.