News & Resources from W. H. Leary

Please use the resources page to search for recent articles, press releases, case studies, videos and industry articles. Check back often as content is updated frequently. Also, feel free to follow us on our social channels.

Tinley Park, IL – August 18, 2025 – W. H. Leary Co., a global leader in advanced inspection, adhesive application, and data collection solutions for the paperboard packaging industry, proudly announces the acquisition of Linemods, a premier manufacturer of high-speed ...Continue Reading

What they see is what they judge. Print defects aren’t always obvious on the line. But to your customer, they’re glaring. Whether it’s a missing logo, blurred barcode, or off-colour branding, a single carton slipping through unnoticed can put your ...Continue Reading

W. H. Leary and EyeC Technology sat down with Nick Stober, Director of Quality Systems and Compliance, and Wanda Speer, Marketing Manager, from Colbert Packaging, Kenosha, WI, USA, to discuss their print inspection solution and the impact it has made ...Continue Reading

In the fast-paced world of packaging; precision, speed, and quality assurance are more crucial than ever. Leary’s latest innovations in glue application and inspection technology together are setting new benchmarks for performance and sustainability in the folding carton industry. With ...Continue Reading

Colbert Packaging, Kenosha, WI, USA, a leader in the pharmaceutical and healthcare packaging industry, needed a robust solution to ensure defect-free shipments, improve operational efficiency, and maintain compliance with industry standards. To address these challenges, the company integrated the LearyVIEW ...Continue Reading

Tinley Park, IL – May 9, 2025 – W. H. Leary proudly participated in the TICCIT program—Trees into Cartons, Cartons into Trees—this Earth Day, reinforcing its commitment to sustainability and community engagement through environmental education. TICCIT, an initiative of the ...Continue Reading

W. H. Leary’s LATAM office in Querétaro, Mexico, proudly marks its second anniversary since opening in 2023. This milestone represents a significant step forward in establishing the company’s presence in the growing folding carton market within Mexico and the broader ...Continue Reading

W. H. Leary Company is pleased to announce a strategic agreement with Doug Herr of Herr Packaging Solutions. Doug will help Leary grow its market share in both Folding Carton and Corrugated markets. “Doug’s 48 years of industry experience will ...Continue Reading

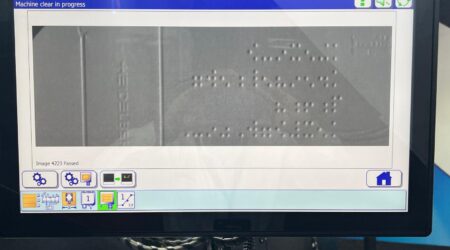

During Expografica 2024, in Mexico City, MX, Leary displayed their LearyVIEW Braille camera inspection solution on Heidelberg’s MK Diana Pharma folder gluer. “Braille inspection on folding cartons plays a critical role in ensuring compliance and accessibility within the pharmaceutical industry ...Continue Reading

Basildon, UK – 9th December 2024 – W. H. Leary, a leading provider of innovative solutions for the paperboard packaging industry, is pleased to announce continued expansion in the UK and Ireland. Over the past year, the company has strengthened ...Continue Reading