Leary’s Monet Operating Software is the control system that automates gluing, quality, and data collection functions for delivering defect-free cartons. Monet 3.2, the newest release, steps forward as a next-generation control system.

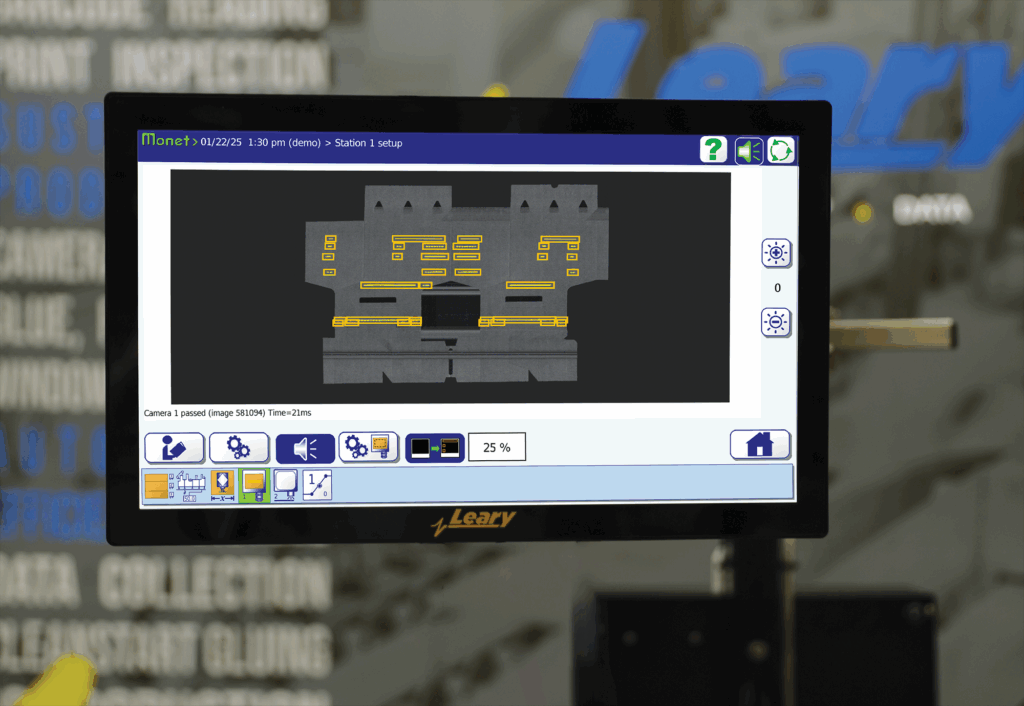

Monet 3.2 leverages the new 55 cm (22-inch) widescreen display in a layout that maximizes the control center. At the core, Monet 3.2 software is built around ease of use for operators; by minimizing complexity, reducing training time and automating the process, factories can leverage advanced technologies without a steep learning curve.

Monet 3.2 integrates camera inspection technology configured directly from the Monet interface, removing dependence on additional screens. LearyVIEW Flex includes multi-inspection capabilities for glue, skew, flaps, and folds. Setting a single camera for multiple applications saves significant setup time. Glue inspection using Flex cameras monitors glue with a variety of field-of-view options to determine where glue should and should not be applied. Equally useful in straight-line gluing and complex beverage cartons, Flex inspects these key quality aspects at once with visual feedback to the operator allowing issues to be fixed in real-time, maximizing production output.

Another camera technology integrated into Monet 3.2 is the latest iCode camera for mixed copy inspection that reads 1D and 2D codes in any orientation, at the highest speeds. This camera technology tolerates minor print variation much better than laser readers, minimizing waste.

Completing the lineup of cameras is the iCheck smart camera that includes a flexible library of inspection tools for labels, inserts, text, date codes, flaps and more with on-screen “point-and-click” setup and finally, LearyVIEW Braille that inspects embossed Braille for presence, register and placement.

During the production process, images of rejected cartons can be viewed directly on screen and Monet will log the specific reason for rejection, assisting operators in taking immediate corrective action.

A further Monet 3.2 feature is the system’s ability to require a barcode / mixed copy inspection ‘challenge’ to be completed at timed intervals, to ensure operators are adhering to factory SOPs. To initiate this challenge, an on-screen alert, buzzer, and beacon light notification is active until the challenge is performed, which is then recorded and time-stamped in the data stream.

Finally, benchmarked settings and sensitive parameters critical for delivering quality are securely locked, with biometric access required for changes. Monet gives maximum access and assistance to operators delivering efficient production, while limiting access to settings that impairs quality. Factories can also utilize Leary’s web-based password portal to ensure only authorized personnel can change critical settings, which are then logged and reported on.

Monet 3.2 offers a strategic advantage to carton production, removing the burden of advanced technology implementation by offering operator-friendly, production-centric software solutions.