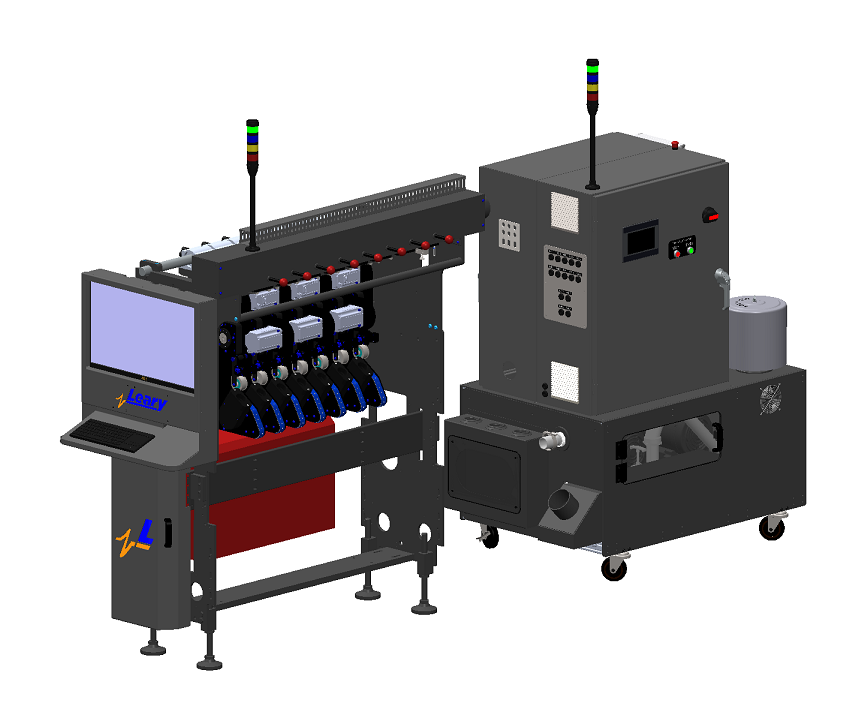

LearyVIEW Print

LearyVIEW Print allows for 100% vision inspection at speeds of 670 m/min (2,198 ft/min) and is capable of detecting print quality, missing copy and color quality.

LearyVIEW Print can be used as a regulatory compliance tool and as a way to gain new customers who require a spot or blanket check on the entire printed side of a carton. With optical character recognition (OCR) and Delta E color inspection, this technology creates the complete solution for the pharmaceutical, cosmetic, food and other industries where flawless print and registration are required.

LearyVIEW Print can be installed in-line, allowing for seamless retrofitting to your existing folder gluer. Achieve impeccable carton quality for your customers and brand owners.

- Eye C Vision technology inspection partner

- 100% inspection for print quality defects up to 670 m/min (2,198 ft/min)

- Detects blemishes as small as 0.11 mm (.006 in)

- 4K or 8K option based on resolution and speed needs

- Individual vacuum transfer belts for accurate product transfer

- Simple operator setup

- Remote monitoring capability

- Carton tracking for rejection

- In-line retrofit solution to most existing folder gluers

- Seamless retro-fitting to multiple machines with mobile solution

- Ideal industries include pharmaceutical, cosmetic, and tobacco

- Preventative Maintenance Program is recommended

Product Transfer Unit

Maximize product inspection with LearyVIEW Print-II’s new transfer unit. This new hardware solution advances product through the inspection station in a consistent way to deliver precise camera inspection.

- Inspect the widest range of carton styles accurately

- Individual and adjustable carrier belts for maximum product control

- Align individual vacuum belts at any carton location for optimum travel through camera inspection unit

- Simple belt maintenance with individual belt replacement

- Ideal for complex structures with multiple cutouts such as pharmaceutical cartons with dividers

- Reduced downtime for maintenance with individual carrier belts

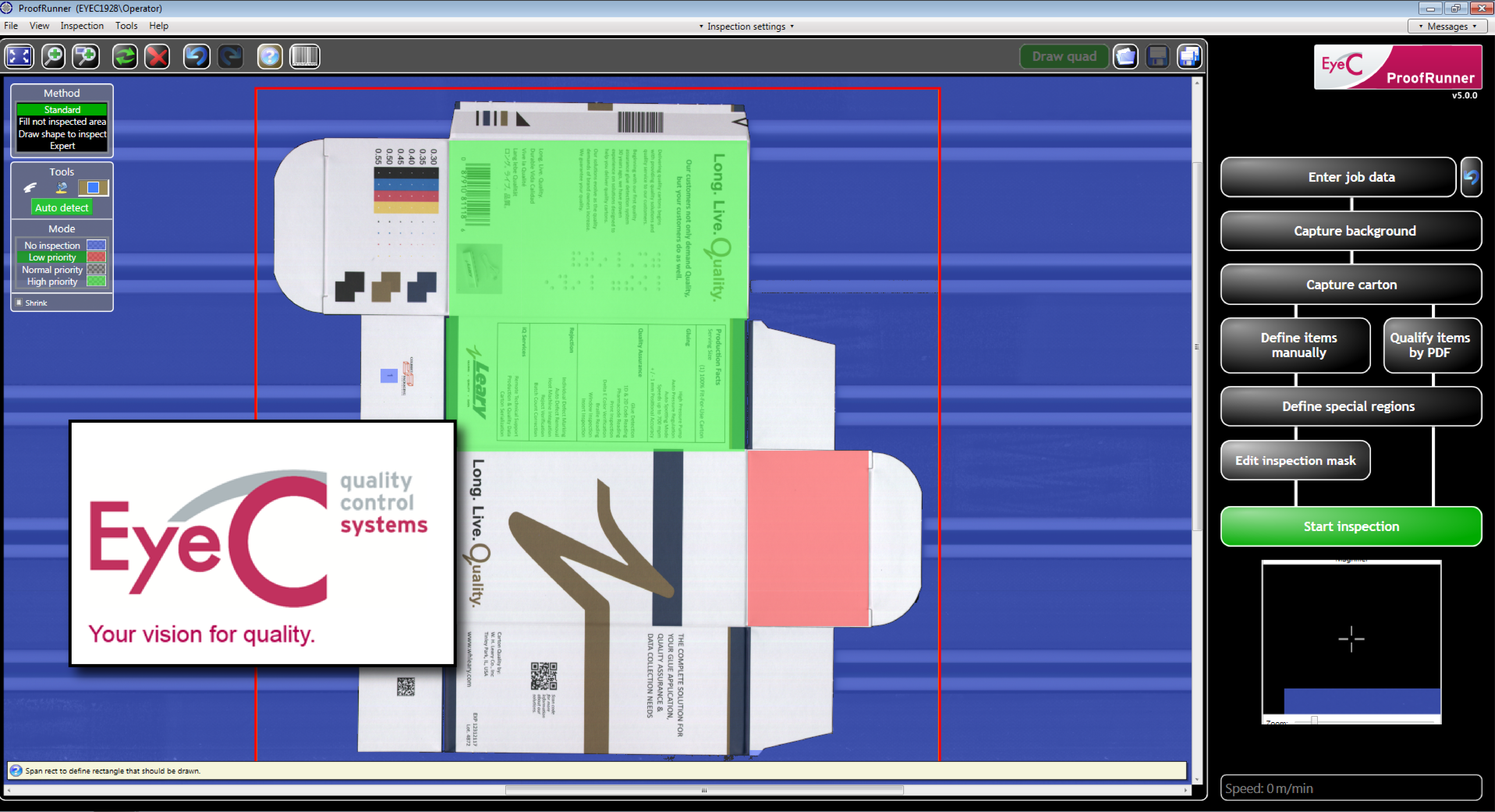

Software Overview

Leary utilizes EyeC vision technology for the most user-friendly, fast, and advanced solutions to identify errors and print defects before they generate losses. The Leary and EyeC partnership provides the folding carton industry with the most precise in-line inspection system from the first artwork file to the finished product. Delta E color inspection capability detects color variations within a sector. PDF comparator to verify print to the original artwork. Automatic setup from enriched prepress PDF.

Solutions For Your Industry

Leary solutions are offered to improve plant efficiencies, decrease setup time, increase uptime and lower product waste, regardless of machine type.