W. H. Leary introduces their new iQ Status production display solution, a visual management tool for plant floors to display real-time, on-the-spot production details. Improving machine efficiencies while continuing to drive enhanced quality continues to be a top priority for folding carton manufacturers. Multiple gluers, frequent product changeovers, tight deadlines and operator skillset can all inhibit on-time and quality product delivery.

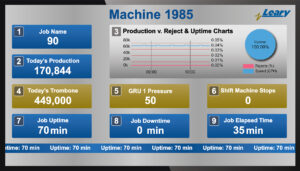

This solution displays user-customizable data related to the machine and the current job onto a large screen for an at-a-glance look at metrics that contribute to success. Monitoring multiple production data points at all times creates an environment of improved productivity and accountability.

The iQ Status displays are mounted over each machine, delivering useful detail for managers and operators. Managing multiple machines effectively is achieved with quick visual reference from the plant floor. In addition, a screen can be located in an office location to monitor productivity of multiple machines at once in the same way. iQ Status is compatible with Leary’s complete line of MaQ+ and Array controllers.

“The addition of iQ Status came directly from customer requests to help them visualize a wider and unique range of data that allows plants to predict problems and maintain quality delivery. Quickly identifying and resolving issue like extended machine stops or reduced throughput is key to production success,” says Andrew Sims, Director of Product Development at Leary.

iQ Status displays are configured using the simple, on-line design wizard which walks users through multiple layout options, reporting categories and detailed data points to report. Plants can choose from over 60 data points to delivery timely information related to machine status, work day info, job and shift info, yesterday’s production information as well as charts and other information components. Each display can use custom colors and logos to create plant uniformity as well as relevant messages to plant personnel.

iQ Status, a module of iQ Smart Services, can be purchased as an independent solution or in conjunction with iQ Dashboard and iQ Alerts. iQ Dashboard is designed to track and aggregate data /reporting over an extended period of time to spot trends and re-occurrences for improvements. iQ Alerts can send instant notifications via SMS or email to personnel when away from the machine. Notifications can include when a machine has been down for a long time, a spoilage rate has been reached, production counts reach a determined value and more.

The iQ Status solution is a simple add-on to Leary’s MaQ+ or Array glue application and quality assurance systems, delivering significant impact in maintaining quality and efficient productivity and creating a culture of accountability.

For more information reach out to [email protected] for a demonstration.