Leary’s advancements in the area of gluing and quality control are in response to a need for improved efficiencies and customers’ requests to adapt to changing needs of the market. Greater quality demands, new and innovative paperboard packaging designs and a continued rise in packaging use, have customers looking for ways to improve their folder gluers delivering drastic results.

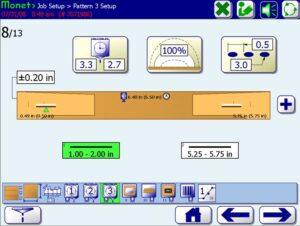

Leary’s Monet software user interface drastically reduces training needed as evident with the simple and quick New Job Setup. Using carton style intel and machine learning, less pages and less button pushes are needed to deliver quick and efficient startups.

The latest Monet 2.12 release features a more secure approach to maintaining carton quality and eliminating human error for repeat jobs by storing defined best-practice settings as a default. Pertinent variables, consistent from job to job are protected from operator changes, when exceptions are needed these changes are easily made through a password retrieval system that generates a unique short-term password for log-in privileges. Changes are recorded, and at the end of the production run Monet defaults these settings back to the original, ready for the next run thus preserving the baseline setup for the future.

Proper and efficient removal of defective product is necessary to maintain production throughput and quality. Leary’s In-Line Diverter ejection system is an upgrade which removes faulty product in a way comparable to the OEM supplied rejection devices on new machines. For older folder gluers, automated rejection devices available removed product by pulling it out from the side of the machine. While this method is viable for some applications, carton styles such as 4-corner, larger or irregular shape can easily create jams when many cartons are rejected together for a line clearance. The In-Line diverter is the only retrofit solution that pushes the cartons down from the machine, eliminating any carton style or size impediments, offering improved machine uptime because setup is virtually nil. Ejectors that remove cartons from the side require high operator skill level, precise mechanical positioning and complex set up –an additional time impediment when trying to get a machine back to production.

Monitoring production output at all times creates an environment of improved productivity. A large flat screen graphical Production Display has recently been added to Leary’s range of visual management products. Along with programmable multi-color beacons, that immediately alert production personnel of a changed or out of specification, these customizable flat screen displays, fitted above each machine, include instant detail about downtime, spoilage, production counts and more. These notification methods are a simple add-on to existing iQ data solutions delivering a significant impact in identifying productivity.

Leary’s solutions remove human touch points and improve automation in a way that maximizes customer’s quality and efficiencies.