Spot Defects First

Stop print errors and spot production issues in real time.

What they see is what they judge

Print defects aren’t always obvious on the line. But to your customer, they’re glaring.

Whether it’s a missing logo, blurred barcode, or off-colour branding, a single carton slipping through unnoticed can put your entire batch – and your reputation – at risk. Most of these errors won’t stop your machine, but they might stop your next order.

That’s why inline print inspection has become essential for carton producers. It gives you eyes on every detail, at full line speed, without missing a beat.

See every carton in full detail

Our inline inspection system works in sync with your gluer line, scanning for faults with pinpoint accuracy. You don’t have to stop the line, slow it down, or settle for spot-checking by hand. Here’s what it delivers:

- 100% print inspection at speeds up to 670 m/min

- Instant detection of missing copy or text barcode and pharmacode errors

- Optional spot-check or full-surface modes

- Fully retrofittable – upgrade your current line, no rebuild required

This isn’t just about catching defects – it’s about guaranteeing consistency, brand integrity and regulatory compliance with every run.

Know everything, all the time

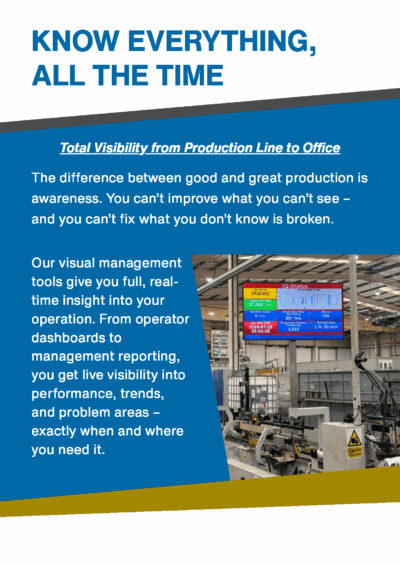

The difference between good and great production is awareness. You can’t improve what you can’t see –and you can’t fix what you don’t know is broken.

Our visual management tools give you full, real-time insight into your operation. From operator dashboards to management reporting, you get live visibility into performance, trends, and problem areas –exactly when and where you need it.

Our dashboards show you:

- Machine speed, output, and uptime

- Real-time carton production and reject tracking

- Downtime logging by cause

- Operator and job-specific performance stats

This isn’t just analytics – it’s actionable insight. It empowers your team to improve shift by shift, not just month by month.

Ready to catch defects before your customer?

With print inspection and production intelligence working together, you can guarantee print quality, reduce waste, and improve accountability – all while running at full speed.

Let’s talk about how to retrofit real-time visibility and inspection into your existing line. Book a live demo or consultation with a gluing and QA expert today.